Thermal Processing Solutions. Engineered to Perform. Built to Last.

New Systems

A new BSP multiple hearth furnace reflects over 100 years of furnace design and innovation. Our proven process generates precision results.

Repairs and Rehabilitation

A well maintained furnace can last over 40 years and you can improve the performance of your unit by upgrading its existing systems.

Engineering

Our experienced engineers will work with you to design a new furnace system that meets your specific needs or get yours back on track.

Inspections

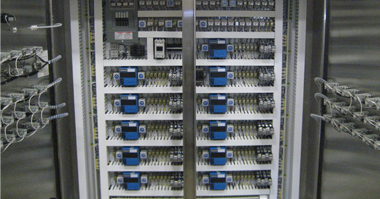

Regular inspections ensure reliable performance. Our inspectors are knowledgeable in all areas of system performance, including mechanical, process, refractory, instrumentation and controls.

EXPERIENCE THE

FURNACE TECHNOLOGY TRUSTED WORLDWIDE

BSP Thermal Systems, Inc. leads the industry in designing and manufacturing high-performance multiple hearth furnace systems. With over 100 years of engineering excellence, we deliver powerful, cost-effective thermal solutions for carbon activation, metal recovery, incineration, ore roasting, and more.

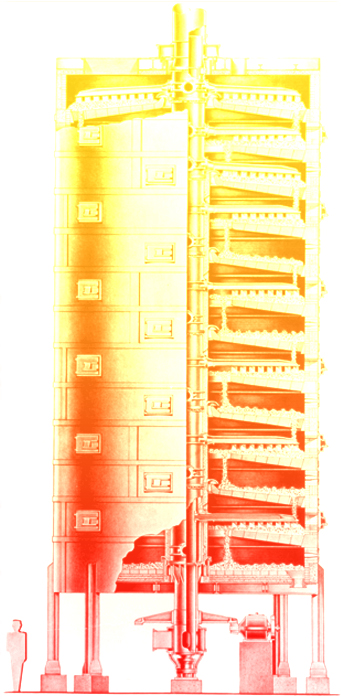

Our multiple hearth furnaces are built for precision and process flexibility. Designed with a vertical, cylindrical steel shell lined with refractory material, each furnace houses multiple hearths stacked one above the other. A central rotating shaft with radial arms moves the material through the system, allowing for controlled exposure to heat and gases at each stage.

This multi-zone approach enables tailored temperature control, enhanced heat transfer, and efficient material movement — all while maintaining low operating and maintenance costs. With customizable features such as gas flow direction, burner placement, and shaft speed control, BSP furnaces adapt to a wide range of materials and process requirements.

Key Advantages of BSP Multiple Hearth Furnace Systems:

- Modular, customizable hearth configurations

- Low NOx burner options and heat recovery systems

- Energy-efficient with countercurrent gas/material flow

- High throughput with a small footprint

- Capable of handling diverse feedstocks with varying moisture and chemical properties

Applications Include:

- Thermal Distillation – Carbon Activation, Regeneration, Charcoal

- Calcination – Lime, Magnesium, Dolomite

- Roasting & Reduction – Copper, Molybdenum, Uranium

- Material Recovery – Cryolite, Mercury, Alumina

- Incineration – Sludges, Pharmaceuticals, Spent Filters

- Drying – Filter Cakes, Concentrates, Foundry Sand

Ready to Build a Better Furnace?

Partner with BSP Thermal Systems and discover how our solutions can transform your process.

Thermal Processing Solutions for Every Industry

From carbon activation to waste incineration—our engineered systems set the industry standard in performance and efficiency.

At BSP Thermal Systems, we understand that every material, process, and industry demands precision and reliability. That’s why we offer a range of multiple hearth furnace systems, each specifically engineered for high performance across a variety of thermal applications. Whether you're activating carbon, recovering valuable materials, or managing industrial waste, BSP furnaces provide the versatility, control, and durability your operation needs.

Carbon Activation

High-temperature systems engineered for producing high-quality activated carbon from a variety of feedstocks.

Carbon Regeneration

Sustainable and cost-effective solutions for recycling spent activated carbon in municipal, industrial, and processing operations.

Char Production

High-efficiency carbonizing systems designed for wood waste, shells, and organic materials with options for steam recovery.

Reduction & Roasting

Metallurgical systems built for high-temperature processing and conversion of ores and concentrates.

Incineration

Environmentally sound solutions that reduce sludges and waste solids to ash, often without the need for auxiliary fuel.

LOOKING FOR A FURNACE PARTNER YOU CAN TRUST?

BSP delivers more than just equipment — we deliver results.